Displacement / Distance Sensors

Scantron are able to offer a range of distance measurement solutions based on varying technologies. With distances ranging from <1mm to over 100m, we can provide a suitable sensor for your distance or displacement requirements.

| Sensor Type | Application |

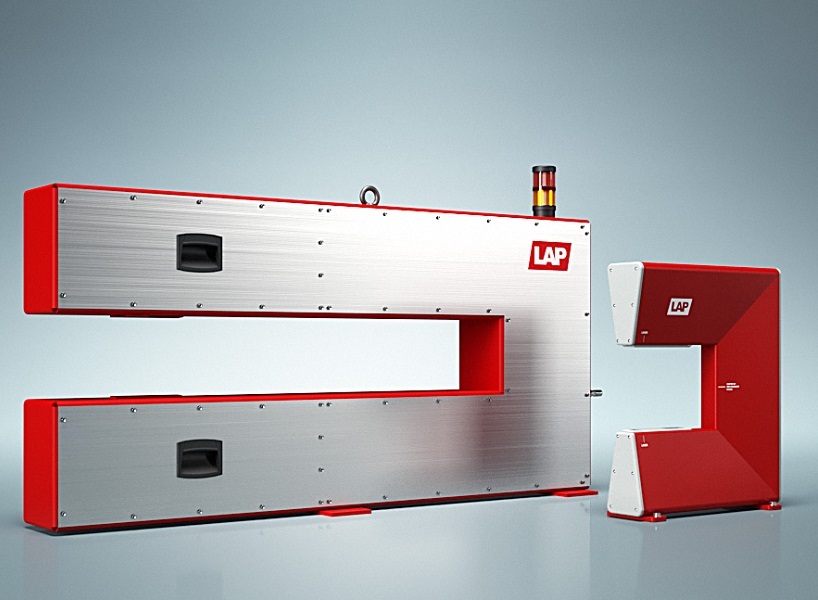

| LAP ATLAS | Laser triangulation with short standoff (10 to 100mm) |

| LAP POLARIS | Laser triangulation with typical standoff (10 to 400mm) |

| LAP ANTARIS | Laser triangulation with long standoff (350 to 4000mm) for hot materials |

| Philtec Fibre Optic Displacement Sensors | Measurement over very small distances for low clearance applications |

| Scantron SLS | Very long standoff measurement up to 30 metres |

Options Available:Comparison Table – Sensor Type

| Distance (mm) | Technology | Output | Comments |

| 0.76~75 | Fibre Optic Sensors | Analogue: 4~20mA Digital: RS232 or USB | Electronics separate to sensor tip D series: output proportional to the target gap and also proportional to changes in reflectivity of the target surface RC series: output signal proportional to the target gap only |

| 10~4,000 | Laser Triangulation | Analogue: 4~20mA RC series: output signal proportional to the target gap only | Enclosed package |

| 100~>30,000 | Phase comparison | RS232, RS422 or RS485 | Enclosed package |

- Connectorised systems available to allow for replacement tips and vacuum pass-through

- Cable jacketing options available offering environmental protection

- Longer cable lengths available on request

- Additional outputs

- Low & high frequency amplifiers

- Digital display

- Low noise amplifier

- Adjustable dc offset

- Blue light source for hot surfaces

- Tip designs & materials available on request

- Sensor amplifier

- Sapphire window for high pressure applications

*not all options available for all sensors