Proscan 2100

Profilometry by Proscan 2100 and Scantron

The Proscan 2100 is a state-of-the-art non-contact surface measurement instrument, equipped with a range of chromatic and laser sensors. The Proscan is capable of rapid three-dimensional surface profiling at rates of up to 1,000 measurements per second, and can achieve precise measurements even on polished or transparent surfaces with a resolution of 5nm.

A suite of available sensors with various working ranges and stand-off heights offers the capacity to optimise the measurement for a variety of surfaces, from medical and dental materials and ceramics to rough paper. The Proscan can be equipped to cater for virtually any measuring need.

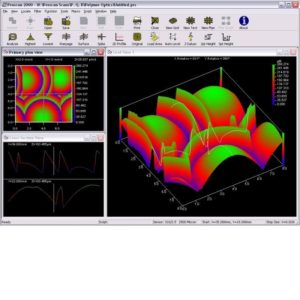

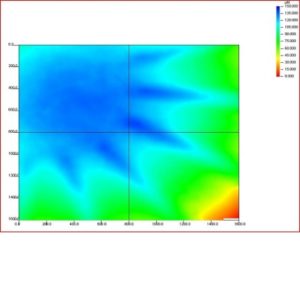

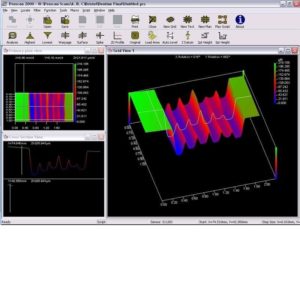

Advanced Metrology Software

The Proscan software package comprises a variety of ISO analytical tools for surface form, finish, and feature geometry, as well as area and volume-based measurements.

In addition to the Proscan 2100, Scantron has developed a range of other non-contact surface measurement solutions, suitable for use across an array of applications and industries. We’re also able to develop entirely bespoke solutions to fit your needs, for both online and offline measurements.

Find the full Proscan range here or contact us for more information.

Contact Our Sales Team

Contact our sales team via email regarding this product: +44 (0)1823 333343

Email UsMake An Enquiry| Sensor Model | Measuring Range | Stand Off mm | Resolution | Linearity (% +/- of range) | Technology |

| S3/011 | 110µm | 3.3 | 5nm | 0.1 | Chromatic |

| S11/03 | 300µm | 11 | 12nm | 0.1 | Chromatic |

| S13/1.1 | 1.1mm | 12.7 | 25nm | 0.1 | Chromatic |

| S16/2.5 | 2.5mm | 16.4 | 75nm | 0.1 | Chromatic |

| S29/10 | 10mm | 29 | 280nm | 0.1 | Chromatic |

| S20/20 | 20mm | 19.6 | 600nm | 0.1 | Chromatic |

| L25/2H | 2mm | 25 | 0.1µm | 0.05 | Triangulation |

| L35/10H | 10mm | 35 | 0.5µm | 0.03 | Triangulation |

| L50/20H | 20mm | 50 | 1µm | 0.03 | Triangulation |

| L70/50H | 50mm | 70 | 2.5µm | 0.03 | Triangulation |

| L270/70H | 70mm | 270 | 2.3µm | 0.01 | Laser |

The sensor naming convention is generally as follows:

First letter – S stands for Spectral (sometimes called chromatic or white light sensor)

First letter – L stands for Laser triangulation sensor

First number – i.e. 5, represents the distance from the target (stand off) in mm that the sensor needs to be at in order to take measurements

Second number – i.e. 2, is the measuring range in mm of the sensor

Hence, an S5/03 sensor is a spectral type sensor with a 5mm stand off and a 300 micron measuring range.

Other sensors are available. Please contact us for alternative ranges.

The Proscan 2100 is a state-of-the-art profilometry system and uses more than three decades’ expertise. We make regular upgrades to the Proscan 2100 system and its software, guided by our client needs and knowledge of the non-contact surface measurement industry.

Our latest upgrades and innovations include:

- Granite frame – the main structure of the Proscan 2100 is produced in granite offering superior thermal characteristics and improved vibrational dampening

- Utilising linear motors and high pedigree stage design, the motors are completely de-coupled from the stage motion, resulting in minimal machine noise being introduced to the scan data

- New motors are much lighter, reducing the mass of the stage and subsequently improving both the smoothness and quietness of stage motion

In addition to these improvements, our flagship profilometry system still retains its already impressive array of features and benefits, including:

- High speed measurement up to 1,000 points per second, coupled with high resolution from 5nm using chromatic aberration, enables the measurement of millions of points on a surface

- A range of interchangeable sensors offers total flexibility within a single system, with measuring ranges in height from 110µm to 50mm and resolutions from 5nm to 2.3µm

- The capacity to measure polished and transparent materials

- Non-contact measurement avoids damage to highly polished, delicate or soft materials

- Scantron’s confocal chromatic sensor technology provides unmatched measuring performance

- With a scanning area of 150mm x 100mm, a diverse range of samples may be measured, making this instrument very versatile and easy to set-up

- Matrix scanning enables arrays of parts to be measured individually or scans can be combined for measuring irregular shapes

- Proscan software was designed to be used intuitively. New users can easily achieve very precise scans with little training, thus making the instrument accessible to all

- With a rugged construction, the Proscan 2100 can be used on the shop floor or in a laboratory, providing precise measurements for many years

- Spot size from just 2µm diameter

- ProForm – specialist software for dental applications; this software package allows for specialised before-and-after analysis of materials subjected to erosion, wear or tribological testing, for use with the Proscan 2100

The Proscan non-contact 3D surface measurement instrument is being successfully used in many industries for non-contact applications where it is important to know the surface characteristics or form of the surface.

- Thin film thickness and layer height measurement

- Dental applications, such as erosion and tooth wear analysis

- Medical applications, such as skin profile analysis using skin replica material

- Embossed material surface characteristics, such as reproduction leather surfaces or synthetic materials

- Layer thickness of screen printed devices, such as electronic or biomedical medical devices

- Detailed surface analysis in 3D of rolled aluminium and steel strip

- 3D surface measurement for forensic analysis

- Measurement of piezoelectric ceramic devices

- Wear of mechanical components to establish change in surface and material loss

- Chemical etching process to determine etch depth and area

- Groove depth and cross section analysis

- Surface warpage and roughness analysis of electronic materials

- Engraving depth on laser etched surfaces

- ProForm – specialist software for dental applications available for use with the Proscan 2100

- Camera for part alignment and image capture

- Vacuum stages for part holding

- Granite topped bench to mount Proscan

- Additional sensors

- Replica material for measuring inaccessible areas and on otherwise difficult to measure surfaces

- Larger X and Y stage travel

- ProForm dental software