Barline

Barline: Online diameter measurement of grinding and bar production

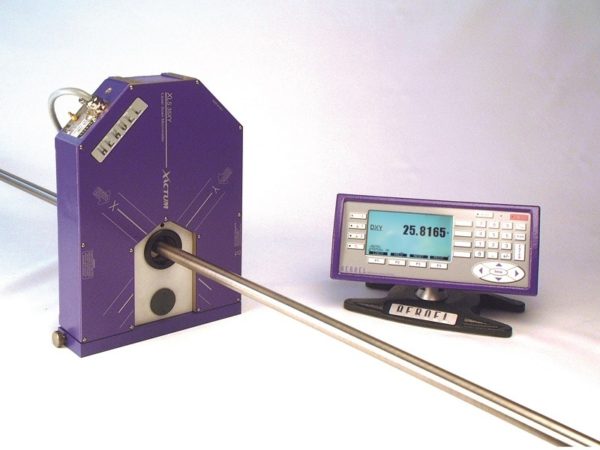

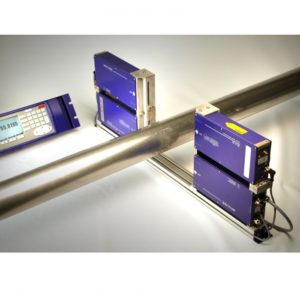

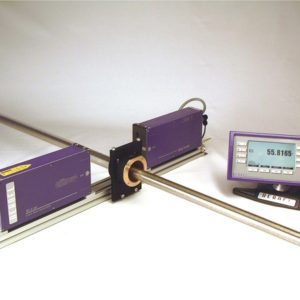

Barline.XY and Barline.X gauges are designed for the online control and measurement of ground bars and drawn metallic tubes, displaying the minimum, maximum and average diameters for each bar with optional head and tail skipping. Tolerance alarms and outputs can be used for go/no-go/rework bar sorting. Ovality measurement can be obtained using the Barline.XY system.

The Barline system includes the new CE-200 operator interface panel, with colour-coded tolerance display and easy programming and product library selection.

- Diameter 0.1 to 149 mm, depending on model

- Resolution from 0.01 µm

- Repeatability from 0.02 µm

- Automated in-process regulation of grinder

- Detailed statistical reports for batches

- 100% quality control

- Bar sorting for reject or rework

- Efficient glass logic for transparent tubes or coated cables

- Accessories available including air-purge windows for gauges, air-blowing rings to clean emulsion from bars, etc.

The experts in laser systems for online diameter measurement

Barline.XY and Barline.Y are developed by Aeroel specifically for bar and tube diameter control in cut lengths. Our clients favour Aeroel for online diameter measurement thanks to its extensive laser systems expertise.

AEROEL FEATURES

- 3-year warranty

- Low sensitivity to vibration owing to exceptional single scan repeatability

- Excellent dust resistance

- Easy-to-use product library with programmed tolerances

- In-built thermal compensation and self-mastering protocols

- Networking ability via Ethernet, even for multiple gauges, to a single computer program

- Data-logging with PC software

- Unique expertise – as a specialist laser micrometer manufacturer, Aeroel have unsurpassed know-how and experience in laser diameter measurement

Contact Our Sales Team

Contact our sales team via email regarding this product: +44 (0)1823 333343

Email UsMake An EnquiryDownloads

| Single Axis | Dual Axis | ||||||

| X40/A | X80/A | X150/A | XY 13/A | XY 13/A/HF | XY 35/A | XY 35/A/HF | |

| Type of gauge | XLS40/1500/A | XLS80/1500/A | XLS150D/150/A | XLS13XY/480/A | XLS13XY/1500/A | XLS35XY/480/A | XLS35XY/1500/A |

| Measuring Field (mm) | 40 | 80 | 150 | 13 x 13 | 13 x 13 | 35 x 35 | 35 x 35 |

| Measurable Diameters (mm) | 0.1 – 38 | 0.75 – 78 | 0.8 – 149 | 0.1 – 10 | 0.1 – 10 | 0.2 – 32 | 0.2 – 32 |

| Resolution (selectable) (μm) | 10 / 1 / 0.1 / 0.01 | 10 / 1 / 0.1 / 0.01 | 10 / 1 / 0.1 / 0.01 | 10 / 1 / 0.1 / 0.01 | 10 / 1 / 0.1 / 0.01 | 10 / 1 / 0.1 / 0.01 | 10 / 1 / 0.1 / 0.01 |

| Linearity (centred product) (μm) | ± 0.5 | ± 1 | ± 3 | ±0.5 | ±0.5 | ±1 | ±1 |

| Linearity (in the measuring plane) (μm) | ± 0.5 | ± 2 | ± 4 | ±1.5 | ±1.5 | ±2.5 | ±2.5 |

| Repeatability (T=1s, ±2σ) (μm) | ± 0.07 | ± 0.2 | ± 0.4 | ±0.15 | ±0.04 | ±0.3 | ±0.15 |

| Single Shot Repeatability (±2σ) (μm) | ± 1.5 | ± 3.5 | ± 5 | ±1 | ±0.75 | ±3.5 | ±2.5 |

| Beam Spot Size (s,l) (mm) | 0.08 x 2 | 0.4 x 3.5 | 0.5 x 4 | 0.1 x 4 | 0.1 x 4 | 0.2 x 4 | 0.2 x 4 |

| Scanning Frequency (Hz) | 1500 | 1500 | 1500 | 480 (X) x 480 (Y) | 1500 (X) x 1500 (Y) | 480 (X) x 480 (Y) | 1500 (X) x 1500 (Y) |

| Scanning Speed (m/s) | 300 | 588 | 940 | 156 | 163 | 288 | 300 |

| Dimensions (mm) | 500 x 134 x 68.5 | 790 x 170 x 60 | 1100 x 282.5 x 140 | 204 x 137 x 49 | 292 x 137 x 49 | 352.5 x 258.2 x 72 | 352.5 x 258.2 x 72 |

| Weight (kg) | 4.2 | 7 | 15 | 2 | 2.5 | 5.8 | 5.8 |

VLD (Visible Laser Diode); λ = 650nm

- No customer rejects or later complaints: the continuous online inspection allows detection and sorting of any out-of-tolerance parts

- Reduction of scrap and material savings: the real-time process control keeps the product within the tolerance range

- Labour savings: the operator’s task is made lighter by the unsupervised grinder regulation

- Quality certification made easier: the 100% inspection makes random sample checks redundant and allows the printing of detailed reports to prove product quality and process capability

- Insensitive to bar vibration and movement: the non-contact laser operating principle enables through-feed inspection, without having to stop or slow down the product

- The oil doesn’t affect the gauging accuracy: due to the compact size of the gauges and specially developed accessories, it is possible in most cases to install the sensor just after the grinding wheels and before the oiling device, in such a position the bar can be easily cleaned by blowing away the coolant

- High precision: the system is fitted with a patented self-calibration device which guarantees permanent gauge accuracy with no re-mastering required

- Straight forward operation: guided menus ensure maximum ease of usage, even for untrained staff

- Competitive price: the favourable cost/benefits ratio ensures a short payback time

- Reliability and long life: the high standards of components and the solid state laser source warrant long operational life

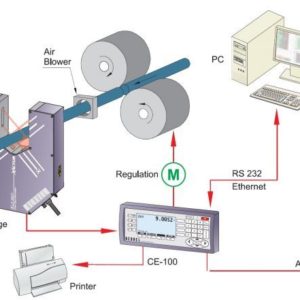

The Barline.XY System is based on an Xactum Laser Gauge, installed at the output of the grinder or drawing bench, which measures very accurately the outside diameter of the product passing through the laser beam. The non-contact operating principle enables through-feed inspection, without having to stop or slow down the product, as its vibration and movement do not affect the gauging accuracy.

The measured average diameter is continuously compared with the nominal value pre-set by the operator: if the product size is going out of the pre-set limits, the Barline.X software automatically adjusts the grinder, recovering the wheel wearing so as to keep the product always within the desired tolerance limits. After skipping the head and the tail, all the readings taken along the bar are stored in memory and compared to the pre-programmed tolerance limits.

By connecting a printer to the control panel, it is possible to get a print-out listing the max, min and average values measured on each part; in addition this data can be recorded and processed to print a final statistical report related to each selected bundle of bars. Through an Ethernet or RS232 serial line, a remote computer can be used to download the measured data or to programme the system.

The basic Barline laser diameter measurement package for ground bars and metallic tubes includes the following functions:

- Display of the measured diameter, of its shift from the set point and of the ovality (*)

- 3 measured values can be simultaneously displayed on the screen

- Programmable skipping of head and tail scans

- Recording of measurements taken along the bar and printing of the values of max, min, avg diameter and ovality (*)

- Programming of nominal value and tolerances

- Real-time and delayed (end of bar) out-of tolerance alarms (Go/NoGo)

- Part sorting signals (Rework/Reject)

- Automatic compensation for product thermal expansion, by programming the temperature and the expansion coefficient

- Library of parameters for 1000 different products, directly retrievable by the operator

- Possibility of entering a password to restrict the programming functions to authorised personnel

- Ethernet / Rs232 interface for remote programming or data retrieval

- Multi-lingual menus (Italian, English, French and German)

- Selectable measuring unit (mm or inches) and resolution

- Pre-programmed factory set-up to facilitate installation and start-up of the system.

The additional Process Regulation module (Option 1) features the following functions:

- Software for automatic diameter regulation, by adjusting the distance between the grinding wheels

- PI (Proportional-Integral) mode, using INC (+) o DEC (-) pulse trains, whose number is proportional to the amount of the required correction

- Regulation is started after having positively checked a real trend to drift from the nominal set-point

- Control parameters can be programmed and stored in the product library

- Automatic backlash recovery, by adding extra pulses each time the correction is reversed

- Separate averaging time for feed-back: it may be set longer than the averaging time for tolerance checking, usually programmed to be as low as possible to detect even shortest diameter flaws

The additional Statistics module (Option 2) offers the following functions:

- Processing and printing of a report for each batch of bars (bundle)

- The max, min, avg, Cp and Cpk values for each parameter recorder on the bar (max, min, avg diameter and ovality) are computed and printed

- The bundle can be selected manually by the operator or determined automatically via a Start/Stop input signal

- Identification of the order and of the operator, with automatic progressive numbering of the bundle

- Statistics can include all the bars of the bundle, or it can be restricted to the good or rejected bars only

- All reports show the date and time