Proscan Magnum – Bridgnorth Aluminium

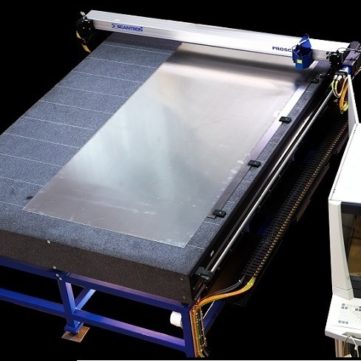

The Proscan Magnum system has been rapidly established as the benchmark for offline shape management of aluminium strip, other flat sheet materials, and panels. With demands for higher quality and flatter materials than ever before among end users, the Proscan Magnum has been developed to make these requirements a reality.

As a result of stresses within the rolled and levelled strip, a residual shape remains in the material, resulting in edge buckle or centre buckle. When a sample of a strip is laid on a perfectly flat surface, its shape can be measured by the Proscan Magnum which scans the strip at specified intervals determined by the user. The identification of surface shape eliminates issues regarding uneven surfaces which, if not discovered, could have detrimental effects on the fit or appearance of the material.

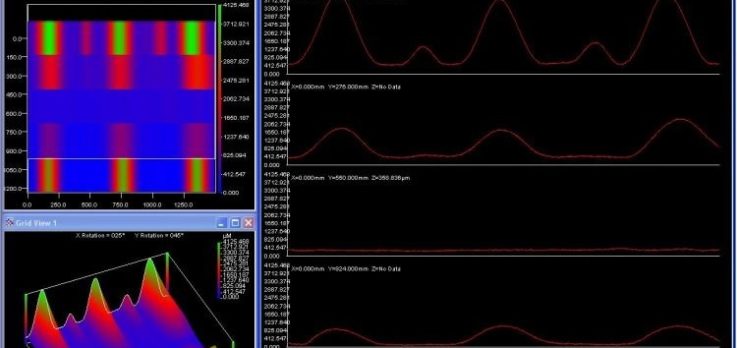

The measurement process is achieved with a precision laser displacement sensor. The wave height, waves per metre and ‘I’ units are measured during each scan for maximum operator feedback. Furthermore, the width, length and diagonal attributes can be measured independently of one another, with the option of user-defined thermal compensation for dimensional accuracy. Results and graphs are displayed on the screen alongside the automated flatness measurement, allowing the operator to view the flatness of each scan for guaranteed accuracy.

Check out our other projects and systems on the previous page to discover other innovative methods towards solving industry problems and see the potential of what we can do for you!