Board

Precision non-contact measurement for plasterboard and gypsum

Scantron is a proven provider of non-contact measurement solutions to industry. Our range of sensors and laser encoders facilitate a number of both online and offline measurements and control of plasterboard or gypsum board dimensions, for quick, accurate and precise data on demand.

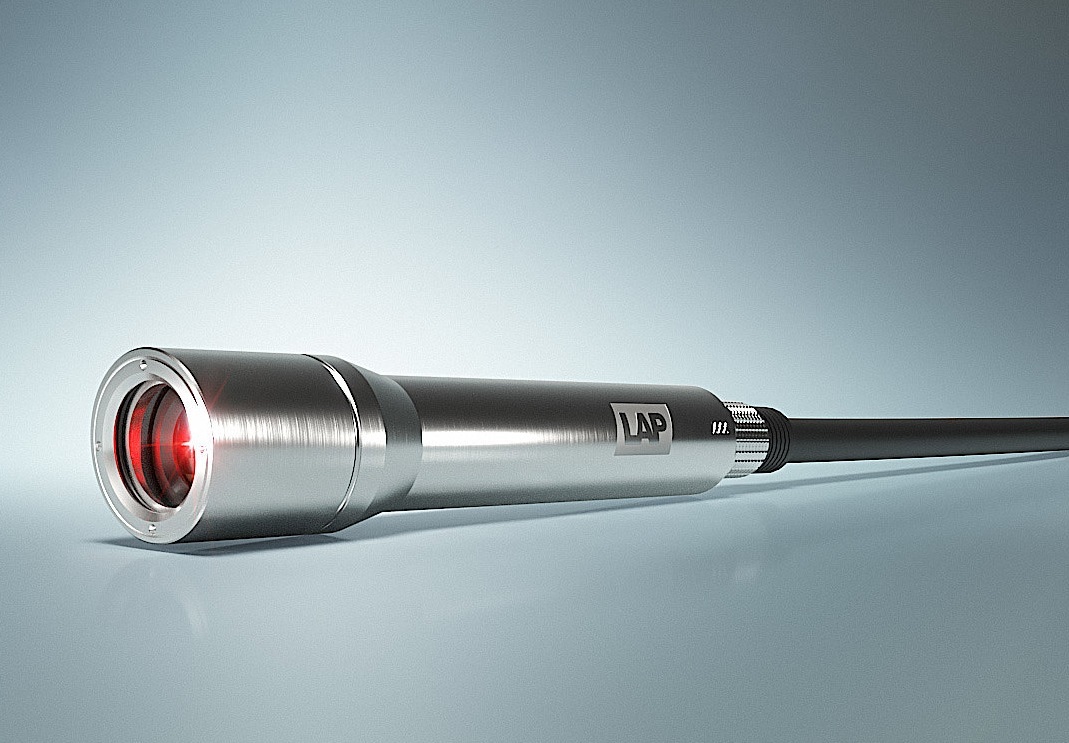

For measuring speed or accurately controlling board cut length, the InteliSENS range of non-contact laser doppler gauges offers a non-contact, zero slippage solution. In many cases the InteliSENS range can directly replace an encoder wheel, which may be prone to slippage, vibration and wear or dirt and grease accumulation. Not only does this increase accuracy and productivity, it also provides a more streamlined solution and results in a low cost of ownership with no need for recalibration.

Flexible measurement to suit existing production lines, labs and factory floors

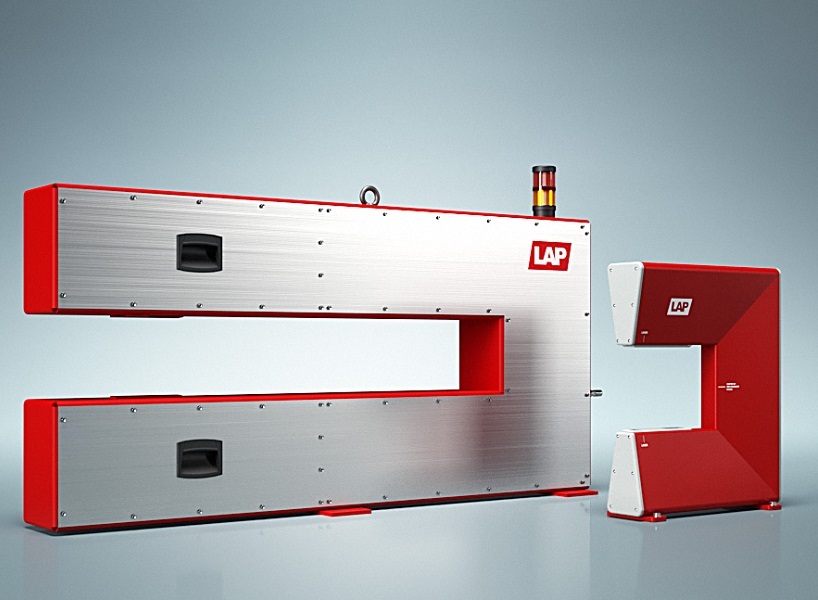

Online thickness measurement of board or gypsum during production can be carried out using the CALIX or MasterTrak non-contact measurement systems, as dictated by the exact requirements of the line.

Scantron’s MasterTrak system also has the capacity to measure width, top and/or side profile of board products during production of piece and continuous products. This helps to provide real time feedback to operators or provide process automation as appropriate.

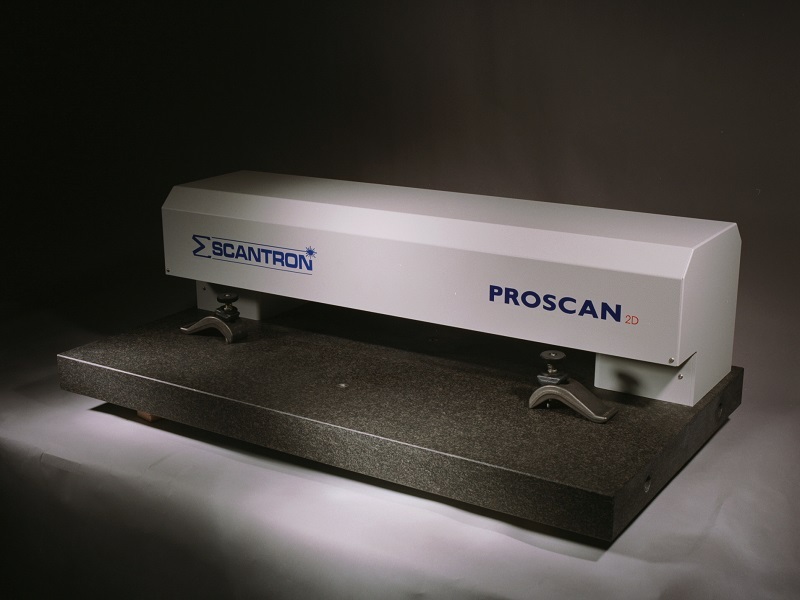

Automated and reproducible offline measurement of board width can be quickly and easily achieved with the Proscan 2D surface profilometer. With the capacity for automated edge detection and taper detection, the Proscan 2D allows quick and repeatable analysis and storage of data on width, height, bow, flatness and roughness. The Proscan 2D is a perfect fit for the lab or factory floor owing to its robust frame, sophisticated software and ease of use.

Get in touch with the Scantron team to find out more about our zero slippage, non-contact measurement for plasterboard and gypsum.