About Us

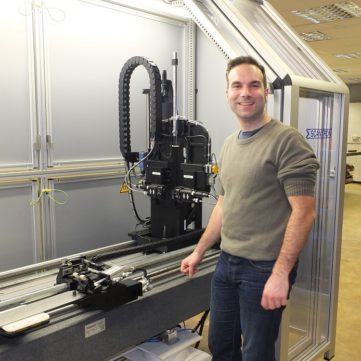

Welcome to Scantron, the first name in non-contact measuring equipment

Founded in 1981, Scantron was an early pioneer in the field of dimensional non-contact measurement. Now with over 40 years’ experience in the field, Scantron has a significant number of systems installed in both offline and in-process applications. Scantron has worked with many industries including; Steel and Metals, Electronics, Medical, Dental Research, Aerospace, Defense and the Nuclear Industry as well as Universities around the world.

Our success has been accomplished by working closely together with our customers to achieve perfect solutions. Scantron’s philosophy is to combine its unique, deep experience and knowledge in non-contact measurement with our customers’ knowledge in their own field. This has resulted in very powerful solutions–many of which are unique.