Steel & Metal

Non-contact measurement for steel and aluminium

Scantron has a long history within the steel and aluminium sectors. A number of the systems in our standard range today were designed on the back of the specific requirements of this industry.

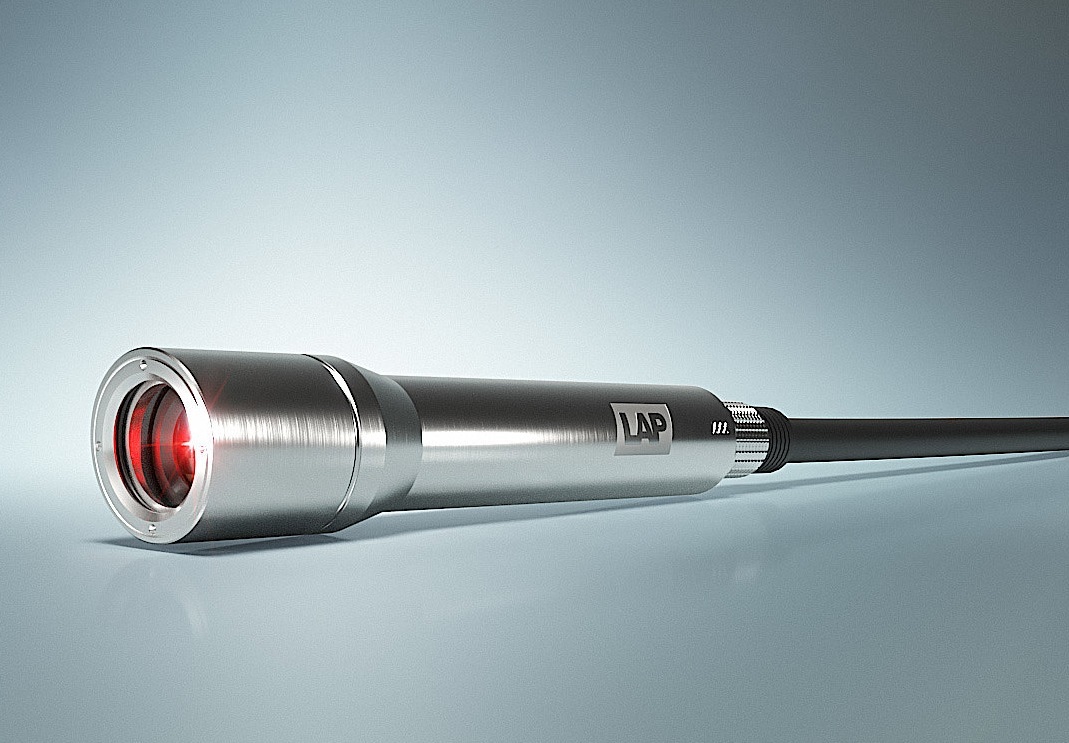

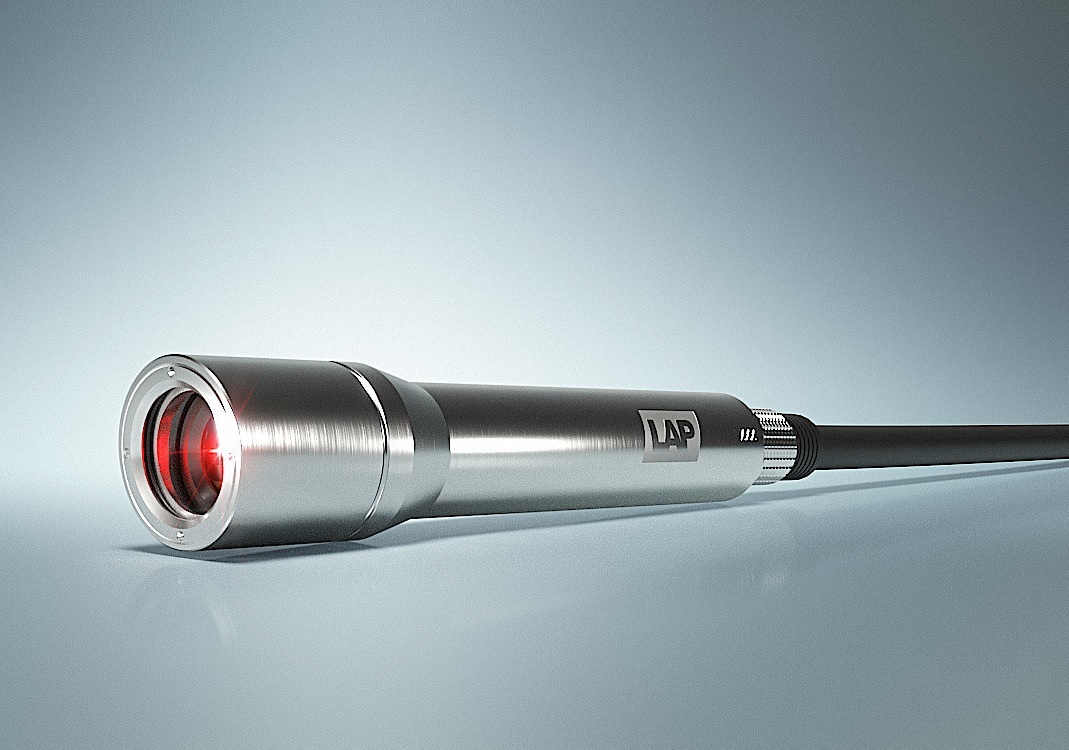

For measuring speed or accurately controlling strip cut or finished length, the market-leading InteliSENS range of non-contact laser doppler gauges is non-contact and a zero-slippage solution which can often be used as a like for like replacement for an encoder wheel. This is a more precise, accurate and economical solution as an encoder wheel may be prone to slippage, vibration, wear or dirt/grease accumulation. The InteliSENS range additionally offers a low cost of ownership and there is no need for recalibration, which keeps operational costs lean and productivity high.

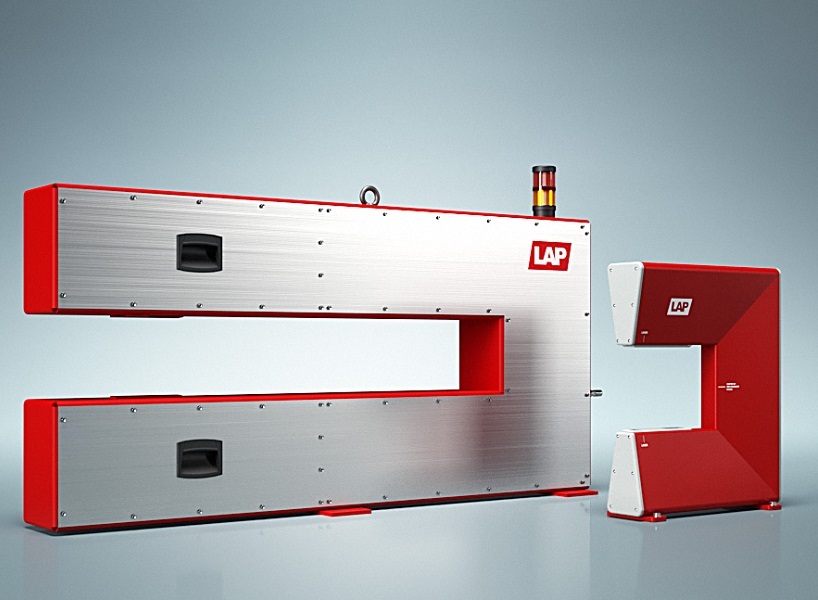

CALIX thickness gauges can be used for online thickness measurement of strip. These gauges represent a plug-and-play solution to the issue of thickness measurement, with a design intended to reduce calibration and remastering requirements as much as possible. Compared to X-ray or isotopic gauges, cost of ownership is considerably lowered by using laser thickness measurement.

Proscan 2D and automated edge detection

Automated and reproducible offline measurement of strip or plate width can be quickly and easily achieved with the Proscan 2D surface profilometer. With the capacity for automated edge detection the Proscan 2D allows quick and repeatable analysis and storage of data on width, height, bow, flatness and roughness. The Proscan 2D is a perfect fit for the lab or factory floor owing to its robust frame.

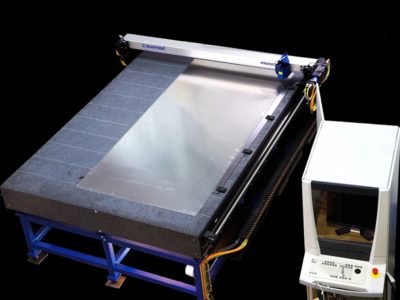

For full flatness measurement and quantification, we developed the Proscan Magnum specifically for the aluminium litho industry. Proscan Magnum is an automatic scanning shape table for precise measurement of the flatness and shape of large products such as aluminium lithograph and steel strip. The system comprises a large (3.5 x 2.5 m) granite table with exceptionally low run-out, combined with a scanning gantry system capable of scanning at over 1 m/s. Dimensions and flatness (’I-units’) are measured by the automated software protocols.

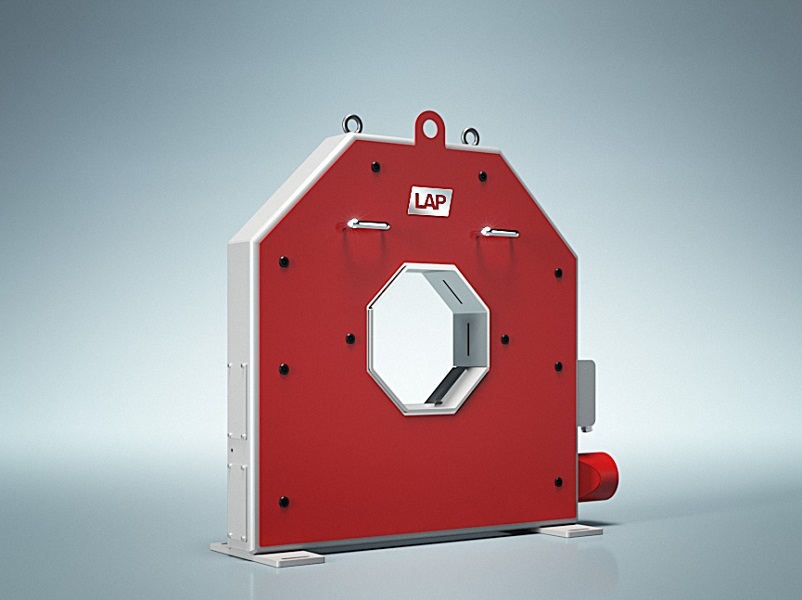

Additionally, we offer ContourCheck, a proven solution for full in-line laser measurement of hot or cold wire, rod, bar or tubes either before or after rolling or finishing. ContourCheck measures the dimensions of round, square, hexagonal, or shaped profiles and can even detect changes in shape over time as well as identifying and categorising rolling defects. Tolerance alarms allow for quick operator intervention, saving time and money. Individual surface defects can also be identified.

Contact us to find out more about our specialist online and offline non-contact measurement systems for steel and aluminium products.