Mini SLR

Bidirectional speed/length measurement

The SLR mini series gauges offer speed and length measurement for bidirectional production lines. The gauge senses the direction of motion and will automatically increment or decrement the length accordingly. SLR mini gauges are thus suitable for production lines that undergo direction reversals or stationary (zero speed) periods.

The SLR mini series of laser speed and length gauges provide highly-accurate, non-contact speed and length measurement. Compared to traditional contact wheel encoders, SLR mini non-contact speed and length gauges offer the following advantages:

- Capable of measurement at much higher speeds and accelerations

- No slippage

- Greater accuracy

- No wear or damage to the measured object

- Solid state design results in higher reliability and MTBF

RS-232 and Ethernet communication interfaces are installed as standard for straightforward connection to computers or PLCs. One optional industrial standard communication interface (PROFIBUS, EtherNet/IP or DeviceNET; replaces the standard Ethernet interface) may also be installed in the gauge.

User configurable digital inputs are provided as standard to reset gauge measurements and trigger printing. User configurable digital outputs are provided as standard to signal gauge status and pre-set length reached.

Contact Our Sales Team

Contact our sales team via email regarding this product: +44 (0)1823 333343

Email UsMake An EnquiryDownloads

| Specification - Zero-speed and bidirectional | Units | SLR1220 | SLR3060 |

| Minimum speed | m/min | 0 | 0 |

| Maximum speed | m/min | ±5000 | ±5000 |

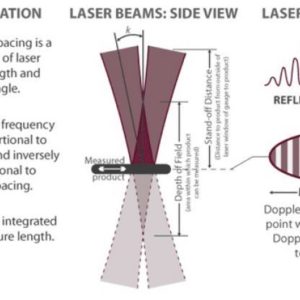

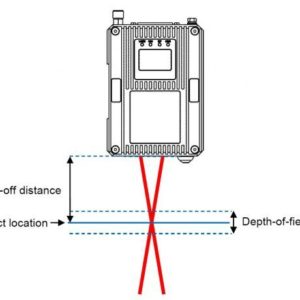

| Nominal stand-off distance | mm | 120 | 300 |

| Depth of field | mm | 20 | 60 |

All Models above have the following Specifications:

| SLR | |

| Accuracy | Maximum 0.05% |

| Repeatability | Maximum 0.02% |

| Maximum acceleration | >1000 |

| Internal measurement rate | 200kHz |

| Measurement update time | 200 kHz internal and 20µs at the outputs |

| Power requirement | 24Vdc, 8 Watts |

| Protection rating | IP67 (harsher envoronments possible with an optional environmental enclosure) |

| Operating temperature | 5° ~ 45°C (higher temperatures possible with an optional environmental enclosure) |

| Gauge dimensions | L x W x H 140 x 105 x 50mm |

| Laser beam diameter | 4mm |

| Laser safety classification | Class 3B |

| Diagnostic display | Integrated LCD |

| Pulse outputs | 2xpluse outputs or 1xquadrature output, freely programmable, pulse rate <1mhz |

| Digital inputs | Laser enable; Shutter enable; 3 programmable inputs |

| Digital outputs | Shutter status; 2 programmable outputs |

| Standard communications interfaces | RS-232; Ethernet TCP/IP (Mopdbus protocol) |

| Display communications | Proton CANbus for optional SiDi-CDI interface display |

| Optional communications interfaces (replaces Ethernet TCP/IP interface) | PROFINET DeviceNet PROFIBUS EtherNet/IP |

- Non-contact, high-speed, solid-state laser speed and length measurement with no slippage, drift, mechanical wear or maintenance compared with contact wheel/roller systems

- Bidirectional speed and length measurement; accurately measures speed and length during line stoppage, reversal and creepage

- Ultra-compact design with a footprint comparable to a smartphone

- Optimised for sheet material and converting applications

- UKAS-traceable calibration; accuracy bettter than 0.05% and repeatability better than 0.02%

- Rugged industrial design for use in facory environments

- Avaliable fitted with industry-standard communications interfaces for easy integration with PLCs and production line equipment

- Excellent value with low cost of ownership

The miniSLR is a very versatile piece of equipment and is suitable for a wide range of applications.

Here’s a short list of some of the industries where our customers have benefited from our non-contact laser measurement systems:

- Flooring and carpet

- Abrasive paper

- Roof foil

- Adhesive tape

- Cold metal

- Paper

- Packaging material

- Construction & insulation material

- Special extrusion and calendaring

- Ceramics

- Cord, lead

- Stranded products

- Insulated products

The following are some of the applications covered:

|  |  |

|  |  |

|  |  |

| AiG2-SL/SLR - Display module Connects via the CANbus port Displays measured speed and length Provides menu-based settings of all parameters Bright VFD dot matrix display |

| AiG2 Panel Mount Kit Bracket for mounting the AiG2 to an end-user panel |

| CAN-bus cable - for connecting the gauge via a PSU-BOB mini to a CDi interface display unit Available in 1, 5, 10, 20, 40, 60 and 100m lengths |

| PCIS SL/SLR mini - PC Interface Software PC-based software package User-friendly graphical user interface Displays all measurements Provides menu-based setting of all parameters Provides trending, data logging, presets and alarms Gauge to PC connection via RS-232 |

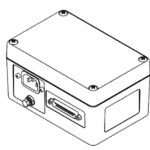

| PSU-BOB mini - Power supply, break-out box and laser safety key switch Connects via the DB25 “INTERFACE” connector Supplies 24VDC electrical power to the gauge Provides screw terminal access to all electrical input and output pins Provides DB9 connectors for access to the CANbus, RS232 and optional industrial bus communications ports Provides a RJ45 connector access to the ethernet port End user cables are sealed with three cable glands Provides a laser enable key switch for compliance with laser safety requirements Input voltage range: 90 – 260VAC @ 45 – 65Hz |

| DB25 Cable - For connecting the gauge "INTERFACE" port to a PSU-BOB mini Available in 1, 3, 5, 10, 20 and 30m lengths |

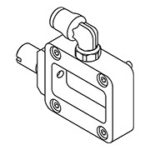

| Terminal Expander - Gauge-mounted break-out bos Connects the DB25 “INTERFACE” connector Provides DB9 connector access to the RS-232, CANbus, Ethernet or optional industrial bus communications ports Provides screw terminal access to all electrical input and output pins End user cables are sealed with cable glands |

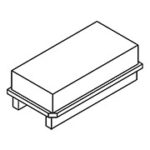

| Industrial Bus Module - For connecting the gauge to industrial communications buses, such as used with PLCs May be retrofitted Protocols: DeviceNET; PROFIBUS; PROFINET; EtherNet/IP |

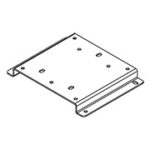

| Base Plate For securing a SL/SLR mini gauge to a mounting surface |

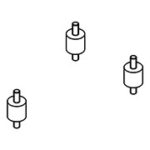

| Vibration Reducing Kit For use with the above Base Plate in high-vibration environments |

| 3D Adjuster Plate For use with the above Base Plate for precision alignment of the SL/SLr mini gauge to the measured object Provides ±3o of roll and yaw adjustment |

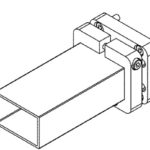

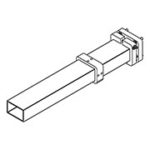

| Laser Protection Tube for SL/SLR mini 1220 Enclosure of the laser beam to within 10mm of the object for laser safety and harsh environments |

| Laser Protection Tube for SL/SLR mini 3060 Enclosure of the laser beam to within 10mm of the object for laser safety and harsh environments |

| Air Wipe High-efficiency, air-wiped protection window for dusty/steamy environments with a quick-change window release mechanism Provides an 8mm push fit tube fitting to connection to a clean air sourc |

| Cooling Plate Air or water cooled plate for installation between the gauge and mounting surface For use in ambient temperatures up to 60°C |